The refractory for lime kiln is selected according to different kiln shapes and actual use. The kiln types for producing active lime include rotary kiln, shaft kiln. In general, there are cocurrent regenerative double-chamber shaft kiln, double beam shaft kiln and ring sleeve shaft kiln.

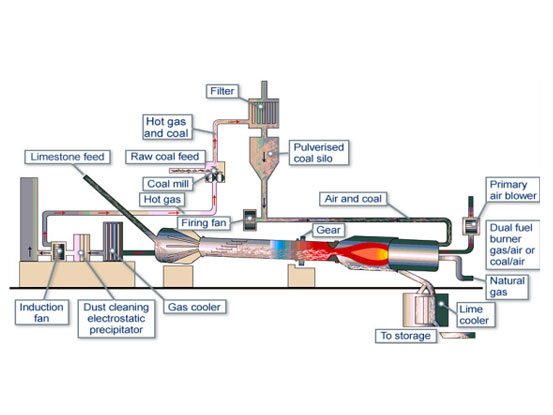

The lime kiln is mainly composed of kiln body, feeding device, preheater, distribution, burning zone, cooler, ash discharge, and dust removal.

Since physical and chemical interactions between the materials and gases in different parts of the kiln are different, the requirements for the refractory materials used in different kiln areas are also different.

1. Preheater Zone

In front of the preheater zone is a preheating machine with the working temperature at about 1000 ~ 1050℃. The main requirement for refractory material is high strength, good wear resistance, and certain thermal shock resistance. Generally, dense clay or high-grade clay brick is mostly used, permanent layers are generally not required for masonry.

2.Transition Zone

The working temperature in this zone is about 1200 ~ 1300℃, it is the transition phase of the operation of the limestone to the burning zone. In this phase, temperature changes a lot and part of lime stone has begun to react, so the refractory used in this zone should has better thermal shock stability and strength, Grade-III high alumina brick (Al2O3≧48) can be good choice. At the same time, at this stage, in order to make the material evenly distributed and heated uniformly, preformed brick with the same materials is another choice, also no demand for permanent layer.

3. High Temperature Zone

The high-temperature zone is next to the sintering zone, with operating temperature about 1300 ~ 1400℃. The temperature changes frequently in this zone and requires the refractory material to have a higher refractoriness under load, higher volume stability and better thermal shock resistance. Generally, special high-alumina brick and fire mud are used for direct masonry without permanent layers. High-grade alumina brick (Al2O3≧75) is the best refractory material for this part.

4. Sintering Zone

Sintering zone is the final reaction stage of lime, using a large burner to heat it. The higher lime's activity requirements, the higher sintering temperature. This section uses a permanent insulation layer, and requires the insulation material to have considerable strength to prevent the work layer from being worn and powdered. We suggest using special high-alumina brick, phosphate bonded high alumina brick, high RUL brick, or magnesia bricks, these can be decided according to actual conditions.

5. Cooling Zone

The cooling zone is very short with only a few rings of bricks or castables, and the operating temperature is 1300 ~ 1400℃. Generally, Grade-II (Al2O3≧65)) or Grade-III (Al2O3≧75) high alumina bricks are used with supporting fire mud for wet laying.

6. Cooler

It is a cooling device for finished lime, cooled by a blower. The temperature of the cooled lime is required to be lower than 100℃. The cooled lime enters the silo through a belt, the temperature of the hot air is about 600℃after heat exchange, and it enters the rotary kiln and combusts gas as combustion air. In this zone, clay bricks are used with wet fire mud.

Anyway, appropriate furnace lining can achieve high-efficiency and low-cost production capacity. The refractory bricks and castables for lime kiln should be selected according to the combustion mechanism, wear mechanism, and wear resistance of raw materials under high temperature reaction. SIJIHUO Refractory company is a professional one-stop refractory materials supplier for lime kilns with more than 20 years’ experience. We look forward to cooperating with you, with professional services, good quality products and most competitive prices!